|

Robert A. Leishear, PhD, P.E., PMP, ASME Fellow, Who's Who in America Top Engineer, Who's Who Millennium Magazine cover story, NACE Senior Corrosion Technologist, NACE Senior Internal Piping Corrosion Technologist, ANSYS Expert, AMPP Certified Protective Coatings Inspector, NACE Cathodic Protection Tester, Structural Steel Worker, Welder, Carpenter, and Journeyman Sheet Metal Mechanic, is a Consulting Engineer for Leishear Engineering, LLC, and worked as a Lead Research Engineer (Principal Researcher) for the U.S. Department of Energy's (DOE) Savannah River National Laboratory (IQ = 161). He has also worked as a design engineer, test engineer, and plant engineer in nuclear waste facilities and nuclear fuel reprocessing facilities. Additionally, Dr. Leishear worked as a lead electronic packaging design engineer for military aircraft and missile systems. In this position, he designed the first wireless aircraft radar system, and he patented an electromagnetic interference mechanism to ensure that aircraft radar computer systems remained operational for second strike capabilities in the event of nuclear war, where this mechanism was installed on all personal computers and printers for decades. Dr. Leishear has written more than 210 technical publications on water hammer, nuclear plant explosions, and other research. Publications by the American Society of Mechanical Engineers include two water hammer and piping design books and Honors Journal publications. Dr. Leishear received the Mensa, Copper Black Award for Creative Intelligence for his research on nuclear power plant explosions and petroleum industry explosions. He was appointed as an ASME Fellow for his research on water hammers, which are directly applicable to industrial explosions. Dr. Leishear earned a B.S. in Mechanical Engineering from Johns Hopkins University, and at the University of South Carolina, he earned M.S. and PhD degrees in Mechanical Engineering, and also earned a Master of Engineering degree in Nuclear Engineering. For these degrees he studied, fracture mechanics, water hammer, fluid mechanics, mass transfer, gas dynamics, materials science, fatigue cracking, advanced thermodynamics, reactor thermal hydraulics, risk analysis, engineering law, reactor design, reactor physics, radiation shielding, reactor materials science, nuclear fuel cycles, reactor water chemistry, nuclear material safeguards, finite element analysis, structural vibrations, machinery vibrations, HVAC design, combustion, explosions, and structural analysis. He has also extensively studied nuclear reactor physics, nuclear reactor thermal/fluid modeling, and nuclear reactor fuel design through Oak Ridge National Laboratories, the University of Illinois, the University of Barcelona, and the U.S. NRC; 12 corrosion courses through the Association for Materials Protection and Performance (AMPP/NACE); water treatment classes through the American Water Works Association; 7 combustion courses through the Combustion Institute at Princeton University and CERFACS; 20 Fluent and Ansys computer modeling courses; plus International Nuclear Law at the University of Singapore and International Radiological Protection at Stockholm University in Sweden through the OECD, Nuclear Energy Agency. He also completed two years of full-time training at the DOE, Savannah River Site to understand infrastructure, diesel engines, pumps, compressors, fans, heat exchangers, evaporators, steam systems, air and nitrogen systems, mixing, instrumentation, calibrations, machinery design, fire protection systems, safety analysis, emergency response, radiation worker, electrical worker, first aid, explosion risks, plus 17 ASME courses on pressure vessel design, inspection, and piping design. At SRS, he also studied nuclear industry processes, which included chemistry, radiochemistry, and physics for nuclear waste disposal and nuclear fuel reprocessing. He was also trained for 6 weeks at SRS as an HVAC, electrical, and electronics systems mechanic. Prior to his academic education, Bob Leishear earned his indenture papers through a four-year sheet metal apprenticeship, and he attended six months of training to learn to weld, build steel plate construction, and cut steel with an acetylene torch. www.leishearengineeringllc.com OpEdNews Member for 242 week(s) and 1 day(s) 92 Articles, 0 Quick Links, 237 Comments, 0 Diaries, 10 Series, 0 Polls

Articles Listed By Date

List By Popularity Page 1 of 5 First Last Back Next 2 3 4 5 View All

SHARE

A Fight for Safer Aiken Drinking Water Is Lost - Government Lies Mangle Our Health I must admit defeat, for now, in my fight for safer drinking water in my home town of Aiken, South Carolina. Aiken's coverup and lies have been effective to maintain the status quo for continued city income from preventable water main breaks, which infect drinking water with disease and poison. We, all of us, are the losers.

SHARE

The 2022, Kansas, Keystone Pipeline Oil Spill Coverup Feeding us science fiction has been sufficient to cover up oil spill causes in our country. The Keystone spill is no different. In this case, the government reached an unsupported and fundamentally flawed conclusion to falsely blame soil weight alone for the pipeline failure.

(3 comments) SHARE

Government Lies Keep on Killing Us - A Definition of Murder I sometimes weary of lies that threaten our lives from industrial disasters. Our government never tires from their lies. I publicly accuse government agencies of needlessly killing us, by choosing profits first before our lives.

SHARE

Why is Aiken Covering Up Drinking Water Hazards and Water Main Destruction? Were People Killed? Is There Corruption? Whether people were killed or not is covered up in my hometown. The South Carolina Department of Health told me that the South Carolina Bureau of Vital Statistics provides such information; the Bureau of Vital Statistics told me that the Department of Health provides such information. Stonewalled again! Is there corruption in Aiken?

SHARE

Lincoln County, Kentucky, Gas Pipeline Explosion Coverup by the NTSB By assuming that the 2019 Lincoln County gas pipeline explosion cause was known for the killing of 1 and injuring of 6, a flawed investigation was performed by the NTSB. As long as the NTSB refuses to accept new science, we are at risk of unnecessary burn deaths - perhaps these deaths are acceptable to the NTSB. Without any doubt, PHMSA nd NTSB chose to ignore this legitimate pipeline explosion safety concern.

SHARE

Delaware Vibrio Flesh-Eating Disease Coverup, October 2025 An October 4, 2025 case of Vibrio from raw oysters goes unreported to the public by the U.S. Department of Agriculture. I was hospitalized for six days after my blood pressure dropped below half the normal value. This flesh-eating disease more commonly enters through open wounds when swimming, but shellfish provide an alternative infection path.

(7 comments) SHARE

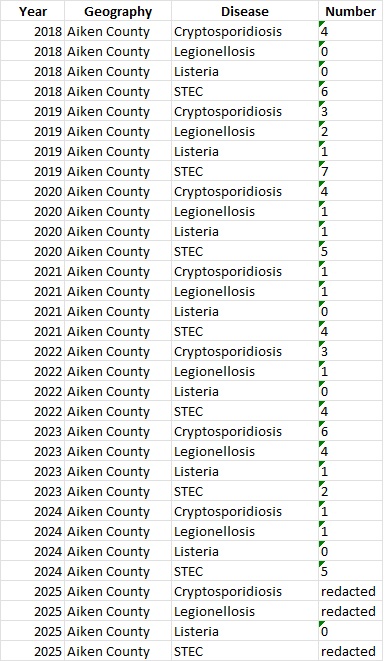

Public Service: Have You Been Sickened by Aiken Drinking Water: Cryptosporidiosis, Legionella, E. Coli, or Listeria Your help could force Aiken to make our water safer to drink, where Dr. Robert A. Leishear plans to address Aiken drinking water safety on November 24, 2025, at the Aiken City Council meeting. Drinking water is a probable cause of illness from Cryptosporidiosis, Legionella, E. coli, and Listeria.

(1 comments) SHARE

The Aiken Diseased Water Coverup is Enforced by the South Carolina Government. The South Carolina Department of Public Health parallels the Aiken City government cover up of public health hazards in our drinking water. Aiken is a microcosm of our national drinking water-safety danger. This Op Ed documents the current status in a fight for safe drinking water, where government agencies control and censor information needed for public health improvements.

(3 comments) SHARE

The Fight for Safe Drinking Water Surges Forward in Aiken There are new technologies that could save Aiken water mains and could stop infectious disease and lead poisoning in the city. I believe that the Aiken City Manager made grievous errors for more than five years with respect to brown-water events and with respect to water main breaks in Aiken. He could save the Aiken drinking water supply. Series: Aiken Covers Up Water Main Breaks and Brown Water and Health Hazards. (7 Articles, 11628 views)

SHARE

Cryptosporidium Reported in Aiken Drinking Water - Hammering Out a Fight Toward Disease-Free and Lead-Free Water A cryptosporidiosis infection was reported in response to one of my Op Eds, when that article was reprinted locally. This article drew the attention of a lady's friends in Aiken, and they contacted her immediately since they knew her Crypto history. Cryptosporidiosis causes 7465 illnesses per year and one death per year. I continue to hammer out my fight to protect our drinking water from disease and lead poisoning. Series: Aiken Covers Up Water Main Breaks and Brown Water and Health Hazards. (7 Articles, 11628 views)

SHARE

The EPA Bullies Us to Pay to Stop City Governments from Lead Poisoning Our Children and Families People are being lead poisoned by government malfeasance and then forced to pay to stop these poisonings. That is, the EPA Lead and Copper Rule requires that people pay to replace lead piping in their homes, while government funds pay for lead piping replacements in their homes. 'Maybe as many as 1.2 million children in the US have lead poisoning.

(9 comments) SHARE

The Real Story of NetFlix's Fundamentally Flawed Documentary, "Titan: The OceanGate Submersible Disaster" This Netflix movie highlighted important concerns about the Titan but bypassed major technical facts. Misinformation by others promoted a fundamentally flawed documentary. An explosion ripped the Titan apart, rather than an implosion. The true story of this explosion disaster was overlooked in this documentary. I stand behind these conclusions as an expert in fluid mechanics and failure analysis.

(1 comments) SHARE

The Titan Submersible Blew Apart in an Explosion Before Partial Crushing - A Fight Against Public Opinion Evidence concludes that a Titan explosion was followed by implosion rather than vice versa. Demonstrating an explosion, the sides of the vessel deformed outward while the top and bottom deformed inward as the vessel formed into an oval shape during the initial explosion. If the vessel had imploded, the sides would have deformed outward. This fact prefaces an understanding of the destruction sequence of the Titan submersible.

(1 comments) SHARE

The Drinking Water Disease Spree; Aiken S.C. is Ground-Zero Preventable infectious diseases and lead poisonings attack us through our drinking water as a national and international travesty. A clear and present danger to our health is certainly known in my hometown of Aiken, the U.S. and worldwide. We are being poisoned and a massive coverup keeps us in the dark. We can and must do better. Series: Aiken Covers Up Water Main Breaks and Brown Water and Health Hazards. (7 Articles, 11628 views)

(4 comments) SHARE

Aiken, S.C. + Drinking Water = Brown Water + Parallel Health Hazards Aiken breaks our mains and then blames residents if they are poisoned. Living in Aiken, I routinely observe the failures of our government to protect public safety in our water system. Today, I fight once again through the Press, where OpEd News is frequently the only weapon for Freedom of Speech and Freedom of the Press to fight our Aiken government to protect us. Series: Aiken Covers Up Water Main Breaks and Brown Water and Health Hazards. (7 Articles, 11628 views)

(1 comments) SHARE

Final Proof of a Titan Submarine Viewport Implosion, Followed by a Hull Explosion - Not a Hull Implosion Experimental data proves that a viewport implosion impacted the Titan to disprove the misconception that a flaw in the hull killed five people in less than the blink of an eye when the submarine obliterated. A fictional story of a flawed submarine hull was repeated so often that everyone assumes that the hull caused the Titan failure. The fact is that an inadequately tested plastic viewport initiated hull destruction. ![[Stop Water Main Breaks!], From Uploaded [Stop Water Main Breaks!], From Uploaded](https://www.opednews.com/populum/visuals/2025/05/2025-05-521540-386-Uploaded-populum_visuals_2025_05_2025-05-521540-rsz_awwa_advertisement-503.png)

(1 comments) SHARE

Aiken, S.C. Officials Destroy Our Water System and Endanger Our Lives and Health Although disappointed that the City Manager seems to control the Aiken government, who choose to keep breaking our water mains to endanger our lives and health, I continue my work to improve public health and stop water main break taxes. Aiken officials will be some of the villains in my forthcoming book, titled "Industrial Murder for Profit in the Water, Gas, Oil and Nuclear Industries". Series: Aiken Covers Up Water Main Breaks and Brown Water and Health Hazards. (7 Articles, 11628 views)

(9 comments) SHARE

A One-Man-Fight Against Small Town and U.S. Water Main Breaks I have a right to fight against water main breaks, using freedom of speech. This right of freedom of speech was crushed by local government. I surge forward in my fight against water main breaks, using freedom of the press. This Op Ed tells part of a story of my ongoing fight against our government. I have rights to fight against water main breaks, to fight against illness and death, and to fight against water main-break taxes

SHARE

The Hudson River helicopter crash and future crash dangers from fatigue crack failures? Fatigue crack failures are prompted by repetitive loads, or vibrations, over and over. Helicopters are massive vibration machines. Therefore, fatigue was a probable cause for this Hudson River helicopter crash. If we do not know the cause, how can we claim that safety is protected?

(6 comments) SHARE

Aiken Coverups and New Scientific Advances in Water Main Breaks The coverups get bigger although science moves forward in Aiken. Aiken had a power outage, I expected water main breaks based on my scientific research, and sure enough there were two near-simultaneous breaks. When I went to one of the water main-break sites, workers were very cooperative at first, but the situation changed. I was blocked from seeing water main damage, and I heard one worker say 'Do you want me to beat him up' Series: Aiken Covers Up Water Main Breaks and Brown Water and Health Hazards. (7 Articles, 11628 views) |